Question: Have you ever wondered why tunnel shipping containers are suddenly popping up everywhere from construction sites to retail storage plans?

What on earth is a tunnel shipping container, and why should you care? At first glance it sounds like something out of Indiana Jones — a mysterious corrugated steel corridor that links two worlds and holds ancient secrets. In reality, a tunnel shipping container is a surprisingly simple but highly practical twist on the classic shipping box we all think of when we imagine global trade.

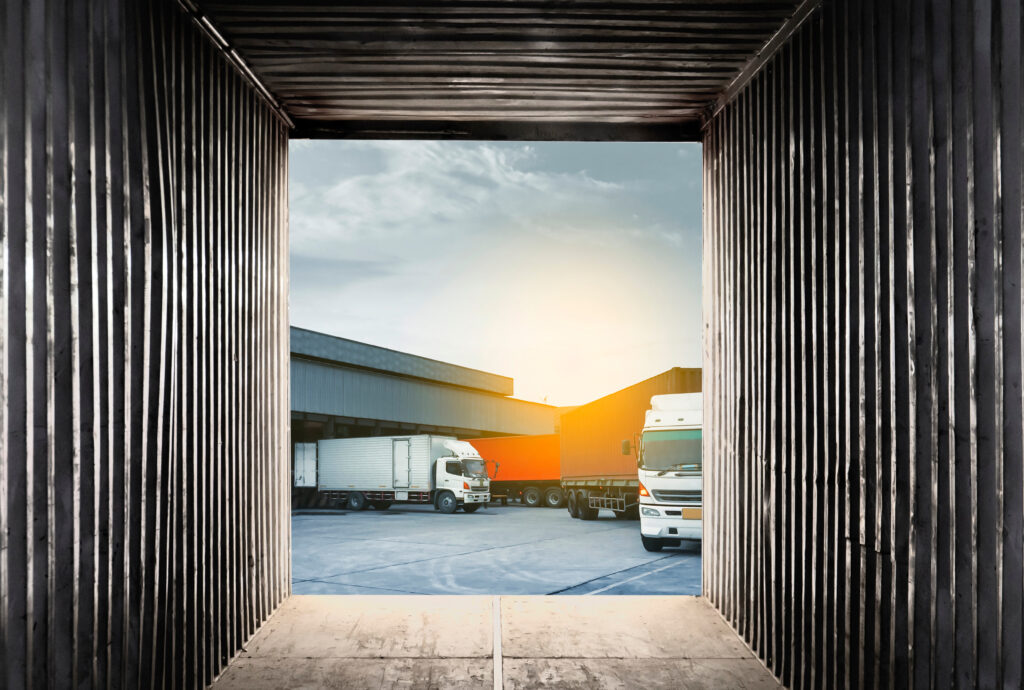

A tunnel shipping container is, in essence, a standard shipping container with doors at both ends rather than just one. This double-access configuration sounds small, but it transforms the container into a logistic powerhouse that solves age-old warehouse gripes: no more contorting yourself to reach stock at the back, no more awkward forklift dance routines, and no more questioning whether that file cabinet really does deserve a place in the office or the storage yard.

Whether you’re a business managing inventory, a site manager juggling tools and machinery, or a creative looking to convert containers into something more inspiring (workshop? retail kiosk? micro office?), tunnel containers deliver flexibility, simplicity, and genuine value. They’re available to buy or hire in both 20ft and 40ft sizes, with options for standard or high-cube height depending on how much headroom you need.

In this article we’ll break down exactly what makes these containers tick, the practical benefits they bring, creative use-cases that go beyond storage, and how they compare to other specialised container types. By the time you’re finished reading, you may well be planning how many of these steel marvels you want on your next project.

What Is a Tunnel Shipping Container?

A tunnel shipping container is simply a shipping container with operational doors at both ends — meaning you can walk, drive or forklift straight through it if needed. This double-ended access is its defining feature and the reason many businesses choose tunnel containers over traditional single-door units.

Key Features:

- Doors at both ends for walk-through or drive-through access.

- Available in 20ft and 40ft lengths.

- Standard height and high-cube height options.

- Secure lockable doors and wind/water-tight build for safe storage.

- Robust marine plywood floor standard on many models.

All of this means you get a container that’s secure and tough (because it’s still made from Corten steel like all shipping containers) but infinitely more accessible than the basic one-door box you’re used to.

Why Double Access Matters

It sounds trivial, right? Just having a second door doesn’t seem like rocket science. But in real-world operations, access is everything.

Ask anyone who’s ever tried to unload half a year’s worth of stock from a traditional container — you’re bending awkwardly, shifting pallets, and basically playing human Tetris. With tunnel containers, you don’t have to:

- Walk or drive straight through to grab items from the middle or back with no contortions.

- Operate forklifts from either end, which saves time and reduces risk.

- Partition the container into two separate lockable units — effectively giving you two units in one.

This last point is huge. With just a stud wall and minimal work, you can split the container into storage + office, retail + storage, or secure stock + workspace — all under one roof. That’s flexibility most businesses didn’t even know they needed.

Tunnel Containers vs Standard Containers

| Feature | Standard Container | Tunnel Container |

| Access | One end only | Both ends |

| Workflow ease | Moderate | High |

| Partitioning | Difficult | Easy |

| Forklift access | One direction | Dual direction |

| Ideal for stocking rotation | Poor | Excellent |

Standard containers are great for shipping and basic storage. But once accessibility and workflow efficiency start mattering (and they always do), tunnel containers begin to shine. This isn’t an upgrade — it’s a redesign for practicality.

Practical Use-Cases by Industry

1. Logistics and Warehousing

Tunnel containers are perfect for warehouses dealing with inventory rotation. The ability to load goods from one side and remove them from the other speeds up throughput and dramatically improves stock control.

2. Construction Sites

If your project stores tools, machinery or materials, having dual doors means workers can reach equipment from the side closest to them — saving steps, time, and frustration. Combined with the container’s rugged steel build, it also provides secure on-site storage.

3. Retail and Event Spaces

Think of a tunnel container as a pop-up shop or kiosk. You can have a retail front queue at one end and storage out the back, or even use the container as a walkthrough gateway for ticketing or security points at outdoor events.

4. Creative Conversions

Tunnel containers aren’t just for boxes and pallets. People convert them into workshops, studios, and even mini offices — utilising the tunnel layout as a corridor through a workspace or sectioning them into functional zones.

What to Consider Before You Buy or Hire

Before investing in tunnel containers (or hiring them), think about:

- Size requirements: 20ft vs 40ft and standard vs high cube.

- Intended use: Straight storage, workspace, or custom conversion.

- Location: Outdoor sites will benefit from wind/water-tight designs.

- Partitioning needs: Easier now than ever with internal studs and doors.

Always talk through your plan with a container supplier — they’ll help specify whether you need standard, high cube, or fitted models based on your workflow.

Case Study: Retail Warehouse Streamlines Stock Rotation

Background: A mid-size retail chain in the UK faced persistent stock access issues at its warehouse. Products were stored in standard containers, and retrieving items from the back required moving a whole pallet stack — time-consuming and inefficient.

Solution: The company switched to tunnel shipping containers for their seasonal stock storage areas. With doors at both ends, staff could load stock from one side and pick orders from the other without relocation or unloading entire pallets. Over three months:

- Fulfilment times improved by 30%.

- Workplace injuries related to manual handling dropped by 18%.

- Operational feedback rated container access as “massively better” compared to single-door units.

By treating each doorway as a workflow entry point, they effectively turned their storage system into a bidirectional staging zone, not just a static warehouse. The result? Smoother operations and fewer headaches. This is exactly where tunnel containers make a difference — not by being flashier than standard containers, but by being smarter.

“Sometimes the simplest change — like adding a second door — is the thing that makes the biggest difference to how work actually gets done.”

If you want storage that works as hard as you do — efficient, flexible, and easier to access — it’s time to explore tunnel shipping containers for your next project. Speak to our specialists and get a quote today.